The logistics industry is at a defining moment. What once relied on manual planning, spreadsheets, and historical assumptions is now being reshaped by intelligent systems that can predict outcomes, adapt in real time, and continuously optimize operations.

In 2026, Artificial Intelligence (AI) is no longer an emerging trend in logistics; it is the foundation of how modern supply chains operate. From forecasting demand weeks in advance to optimizing delivery routes in real time, AI is enabling logistics companies to operate faster, smarter, and more efficiently than ever before.

This transformation is not about replacing human expertise. It is about augmenting decision-making, reducing uncertainty, and creating logistics operations that can respond instantly to change.

In this blog, we explore how AI is transforming logistics operations in 2026, the real-world use cases driving ROI, and how logistics companies can stay competitive in an AI-first future.

Table of Contents

Why Logistics Needs AI More Than Ever

The global logistics ecosystem has become increasingly complex. Businesses are managing cross-border shipments, multi-channel fulfillment, tight delivery timelines, and rising customer expectations, all while facing cost pressure and unpredictable disruptions.

Traditional logistics systems struggle in this environment because they are largely reactive. Decisions are made after issues occur, not before. AI fundamentally changes this approach by allowing logistics teams to anticipate problems, model outcomes, and act proactively.

AI enables logistics companies to:

- Respond dynamically to demand fluctuations

- Minimize delays caused by external factors

- Optimize resources continuously instead of periodically

As a result, logistics operations become resilient rather than fragile.

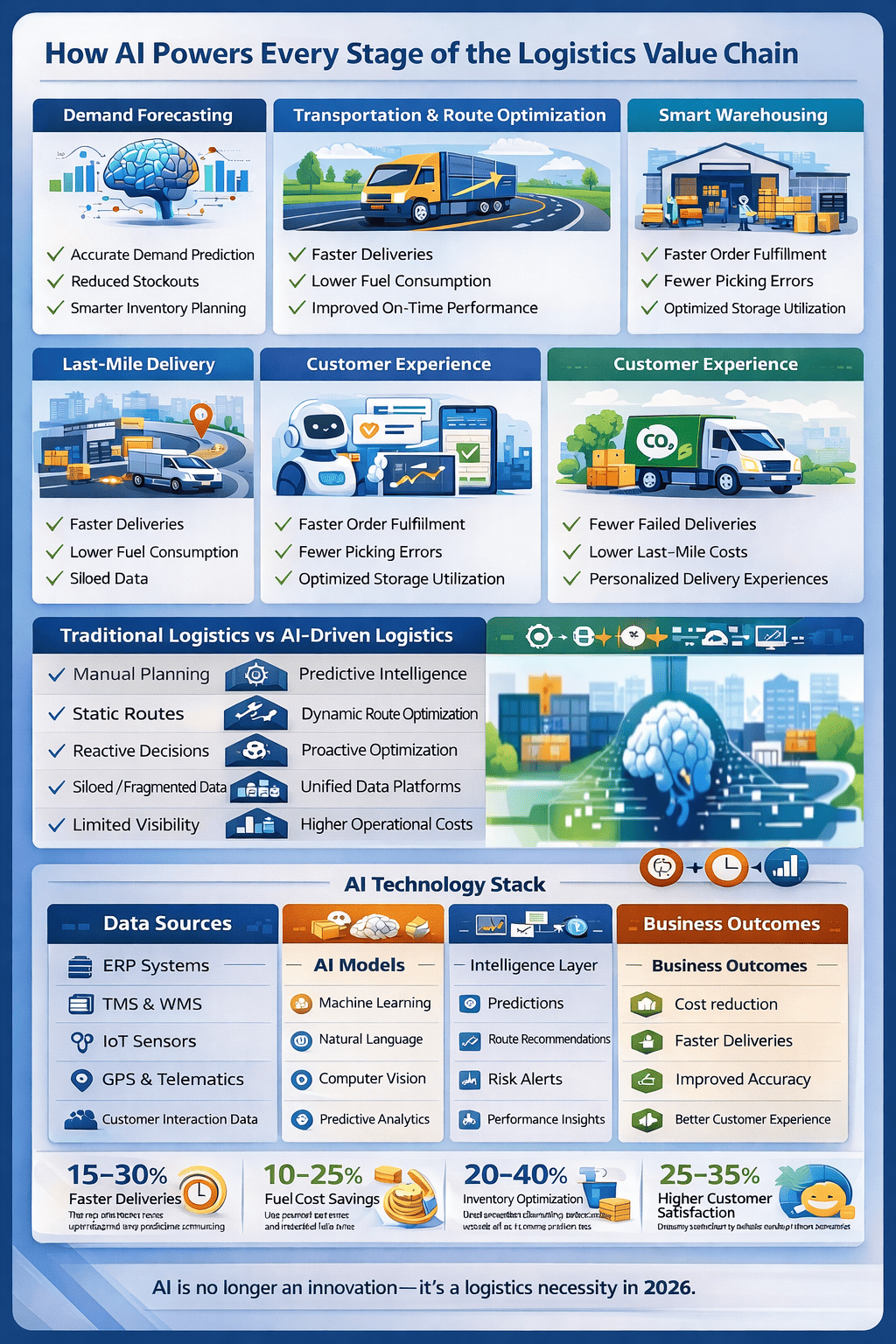

How AI Works in Modern Logistics Operations

At its core, AI in logistics uses large volumes of operational data to identify patterns that humans cannot detect at scale. These insights power predictive and prescriptive decisions across the supply chain.

AI systems analyze data from:

- Transportation Management Systems (TMS)

- Warehouse Management Systems (WMS)

- ERP platforms

- IoT sensors, GPS devices, and customer interactions

Unlike traditional automation, AI systems learn from outcomes. Each delivery, delay, and exception improves the system’s accuracy over time.

This learning capability is what allows logistics operations in 2026 to move beyond static planning and toward continuous optimization.

Smarter Demand Forecasting and Inventory Planning

Demand forecasting has always been one of the most challenging aspects of logistics. Relying only on historical sales data often leads to inaccurate projections, especially during volatile market conditions.

AI-driven forecasting models take a broader and more intelligent approach. They analyze not only past demand but also external signals such as seasonal trends, promotional activity, regional behavior, weather patterns, and economic indicators.

With AI-powered forecasting, logistics companies are able to:

- Maintain optimal inventory levels across locations

- Reduce excess stock and storage costs

- Prevent stockouts that disrupt fulfillment

More importantly, AI enables scenario planning. Logistics leaders can simulate “what-if” situations, such as supplier delays or sudden demand surges- and prepare contingency plans in advance.

AI-Powered Transportation and Route Optimization

Transportation efficiency directly impacts delivery speed, fuel costs, and customer satisfaction. In 2026, AI plays a critical role in making transportation networks more intelligent and responsive.

AI systems continuously evaluate real-time factors such as traffic congestion, weather conditions, vehicle capacity, and delivery priorities. Based on this data, routes are dynamically optimized instead of being fixed at the start of the day.

This results in:

- Faster deliveries through real-time rerouting

- Lower fuel consumption and reduced emissions

- Improved on-time delivery performance

AI also supports predictive fleet maintenance by identifying early signs of vehicle wear and potential failure. Maintenance is scheduled proactively, reducing downtime and preventing costly breakdowns.

Warehouse Operations Powered by Intelligence, Not Just Automation

Warehouses in 2026 are no longer labor-intensive storage spaces. They function as intelligent fulfillment centers where AI coordinates people, robots, and inventory in real time.

AI-driven warehouse systems optimize:

- Picking and packing workflows

- Inventory placement based on demand velocity

- Task allocation between human workers and robots

Computer vision further enhances warehouse accuracy by enabling automated quality checks, package verification, and damage detection.

The outcome is a warehouse that operates with:

- Higher throughput

- Fewer errors

- Better space utilization

AI does not eliminate human roles; it enables workers to focus on higher-value tasks while machines handle repetitive operations.

Revolutionizing Last-Mile Delivery with AI

Last-mile delivery remains the most expensive and complex stage of logistics. AI addresses this challenge by combining predictive intelligence with real-time adaptability.

AI models analyze delivery locations, customer availability, traffic density, and historical success rates to determine the most efficient delivery schedules. This reduces failed delivery attempts and improves customer satisfaction.

In 2026, AI enables logistics companies to offer:

- Accurate delivery time windows

- Personalized delivery preferences

- Proactive notifications for delays or changes

By optimizing routes and delivery clusters, AI significantly reduces last-mile costs while enhancing the overall customer experience.

End-to-End Visibility Through AI Control Towers

Visibility is no longer about tracking shipments; it is about understanding what is happening and why.

AI-powered logistics control towers provide a centralized view of the entire supply chain. These platforms use AI to detect anomalies, predict delays, and recommend corrective actions in real time.

Instead of manually monitoring dashboards, logistics teams receive:

- Intelligent alerts with contextual insights

- Root-cause analysis for disruptions

- Actionable recommendations to resolve issues quickly

This shift from monitoring to decision intelligence is a major leap forward for logistics operations.

AI’s Impact on Customer Experience in Logistics

Customer expectations in 2026 extend far beyond delivery speed. Transparency, communication, and reliability are equally important.

AI enhances customer experience through:

- Conversational chatbots that provide instant shipment updates

- Predictive notifications that inform customers before issues occur

- Sentiment analysis that helps improve service quality

When customers feel informed and in control, trust increases, and trust drives long-term partnerships.

Building Sustainable Logistics Operations with AI

Sustainability is now a strategic requirement, not a compliance checkbox. AI helps logistics companies reduce their environmental footprint while improving efficiency.

By optimizing routes, improving load utilization, and minimizing idle time, AI reduces fuel consumption and emissions. Advanced analytics also help organizations measure and track sustainability metrics across the supply chain.

This allows logistics businesses to meet ESG goals without compromising profitability.

Challenges in AI Adoption, and How to Overcome Them

Despite its benefits, AI adoption is not without challenges. Many logistics companies struggle with fragmented data, legacy systems, and skill gaps.

Successful AI transformation requires:

- Clean, integrated data pipelines

- Scalable architecture that works with existing systems

- Strong change management and workforce training

- A clear roadmap aligned with business goals

Partnering with an experienced logistics software development company significantly reduces implementation risk.

The Road Ahead: AI as the Core of Logistics Strategy

Beyond 2026, AI will enable:

- Autonomous delivery vehicles

- Self-optimizing supply chains

- Fully intelligent fulfillment ecosystems

Logistics companies that invest today will be better positioned to scale, adapt, and compete in an increasingly complex global market.

Conclusion: AI Is Redefining What Logistics Can Achieve

AI is not just improving logistics; it is redefining it.

In 2026, the most successful logistics organizations are those that treat AI as a strategic capability, not a standalone tool. By embracing intelligent systems, businesses unlock efficiency, resilience, and customer-centricity at scale.

Why Webkorps for AI-Powered Logistics Solutions?

Webkorps helps logistics companies design and implement custom AI-driven logistics solutions that integrate seamlessly with existing systems. From smart warehousing to predictive transportation and real-time visibility, our solutions are built to deliver measurable impact. Explore Webkorps logistics solutions, or talk to our AI & Logistics Experts today.

Frequently Asked Questions: AI in Logistics

What is AI in logistics?

Artificial Intelligence in logistics refers to the use of machine learning, predictive analytics, computer vision, and automation technologies to improve supply chain planning, transportation, warehousing, and customer experience. In 2026, AI enables logistics companies to predict demand, optimize routes, automate warehouses, and gain real-time visibility across operations.

How is AI transforming logistics operations in 2026?

In 2026, AI is transforming logistics by shifting operations from reactive to predictive. AI systems forecast demand accurately, optimize transportation routes in real time, automate warehouse workflows, improve last-mile delivery efficiency, and provide intelligent control towers that detect disruptions and recommend corrective actions before problems escalate.

What are the key benefits of AI in logistics?

AI delivers multiple benefits for logistics companies, including reduced operational costs, faster delivery times, improved inventory accuracy, enhanced customer satisfaction, better decision-making, and increased supply chain resilience. It also supports sustainability goals by optimizing fuel usage and reducing carbon emissions.

How does AI improve demand forecasting in logistics?

AI improves demand forecasting by analyzing historical sales data alongside external factors such as seasonality, market trends, promotions, weather conditions, and economic signals. This results in more accurate forecasts, better inventory planning, fewer stockouts, and reduced excess inventory across warehouses.

Can AI help reduce logistics and transportation costs?

Yes, AI significantly reduces logistics and transportation costs by optimizing delivery routes, minimizing fuel consumption, predicting vehicle maintenance needs, reducing empty miles, and improving fleet utilization. These efficiencies lead to lower operational expenses and improved profit margins.

How does AI enhance warehouse operations?

AI enhances warehouse operations by automating picking and sorting, optimizing inventory placement, improving order accuracy, and coordinating human workers with robotics. Computer vision enables automated quality checks and damage detection, resulting in faster fulfillment and fewer errors.

What role does AI play in last-mile delivery?

AI plays a critical role in last-mile delivery by predicting delivery time windows, optimizing delivery routes in dense urban areas, reducing failed delivery attempts, and personalizing delivery preferences. This improves customer satisfaction while lowering last-mile costs.

How does AI improve supply chain visibility?

AI improves supply chain visibility by integrating data from transportation, warehouse, and IoT systems into centralized control towers. These platforms provide real-time tracking, detect anomalies, predict delays, and deliver actionable insights, enabling faster and smarter decision-making.

Is AI in logistics suitable for small and mid-sized companies?

Yes, AI is increasingly accessible to small and mid-sized logistics companies. Scalable AI solutions allow businesses to start with high-impact use cases such as route optimization or demand forecasting and expand gradually as operations grow.

What are the challenges of implementing AI in logistics?

Common challenges include data quality issues, integration with legacy systems, skill gaps, change management, and security concerns. These challenges can be addressed with a clear AI strategy, clean data pipelines, phased implementation, and the right technology partner.

How does AI support sustainability in logistics?

AI supports sustainability by optimizing transportation routes, reducing fuel consumption, minimizing idle time, improving load utilization, and tracking carbon emissions. This helps logistics companies meet ESG goals while maintaining operational efficiency.

How long does it take to implement AI in logistics operations?

The timeline for AI implementation varies based on use cases and system complexity. Pilot projects can be launched in a few weeks, while enterprise-wide AI transformations typically take several months. A phased approach ensures faster ROI and lower risk.

Why choose Webkorps for AI-powered logistics solutions?

Webkorps specializes in building custom AI-driven logistics solutions that integrate seamlessly with existing ERP, TMS, and WMS platforms. Our expertise in AI, data engineering, and logistics technology helps businesses improve efficiency, visibility, and scalability with measurable results.